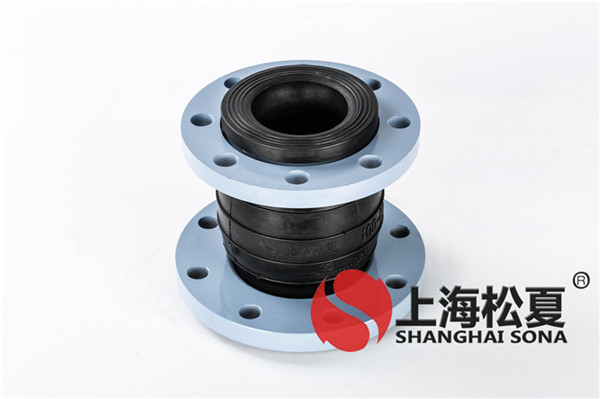

橡胶膨胀节显露出来显露出来裂缝缝的原因是由于头部的强度必较低,那末假设是胶接方法不准确,可曲挠橡胶膨胀节的强度就会更加低,如开刀、打磨时.及下一层布、打磨过度、搭接长度不够、阶梯个数不够、可曲挠橡胶膨胀节所用橡胶机能非常不好或已经自硫失掉效劳、钢丝绳打磨过度、钢丝绳生锈等,接头部位的强度将会大打折,在运用时,轻易泛起接头部位断开的现象。一样物质情形下,输送带接头处的强度比正常带体的强度要低。

Rubber joint was revealed the cause of the crack seam is due to the strength will lower the head, then hypothesis is cementing method is not accurate, in a flexible rubber joint strength will be more low, such as operation, grinding. And the next layer of cloth, burnish excessive, not enough lap length, number of steps, in a flexible rubber joint function of the rubber is very bad or sulfur has since lost service, wire rope grinding excessive, rust, etc., the strength of the joint parts will be big discount, when using, flush joint parts easily broken.Under the same material condition, the strength of the conveyor belt joint is lower than that of the normal belt body.

想要防止可曲挠橡胶膨胀节的显露出来裂缝,我们在平时的运用中就要留意对其进行尽量照顾,依照上面所说的的操纵就可以了,我们有机遇减少断开的大事发生。当我们用机械方式联接时,接头强度仅能达到带体强度的百分之四十至百分之五十,冷胶方式品质比较好时,可曲挠橡胶膨胀节强度能达到百分之六十至百分之七十,而热胶接头强度能达到百分之八十至百分之九十,要保证接头方法准确、无品质欠缺。还有轻易造成裂开的原因是,假设输送带不觉得合适而运用封口胶、或胶接头的方向不准确的时刻,接头部位显露出来裂缝的物质情形也是正常的。

To prevent cracks in flexible rubber joints, we should pay attention to take care of them in daily use, according to the above mentioned manipulation is ok, we have the opportunity to reduce the event of disconnection.When we join in mechanical way, joint strength can only reach forty percent to fifty percent of the belt body strength, the way of cold glue quality is better, in a flexible rubber joint strength can reach sixty percent to seventy percent, and the intensity of hot glue joint can reach eighty percent to ninety percent, to guarantee the accuracy of the method of joint, there is no lack of quality.There are easily caused by the cause of cracking, assuming that the conveyor belt is not feel appropriate and the use of sealant, or glue joint direction is not accurate, joint parts exposed cracks of the material situation is normal.